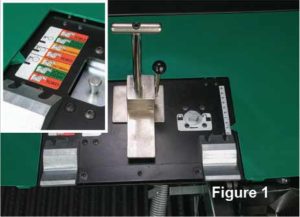

Foley United Figure 1

A New era of Foley United LLC will be unleashed at the GIS in San Antonio. Foley United’s most recent grinder technology has the industry wondering “what’s next”. It’s not about just a new machine, but more about technicians and superintendents having options and a choice when it comes to their reel grinding practices.

While all grinder manufacturers spin grind to a sharp edge, it’s Foley United’s innovation, automation quality, and elegant simplicity that sets the industry standard when it comes to grinding capabilities. The ability to conduct a quick spin grind when wanted or returning reels back to OEM specifications when needed is what it’s all about, which separates Foley United from the competition.

Foley United 633

Not only are there new machine advancements from Foley United, but the company is changing. 2017 brought new company ownership and new senior leadership committed to growing the business. This has already made a big impact with investments in “lean” manufacturing, automation, updated facilities, and expanded product lines that will provide the user with expanded performance and options you are looking for. Stop by booth 16107 at the GIS and see how Foley United will save you time and money making your shop more productive than ever.

Foley United 653

Foley United’s launch of the 653 and 633 Reel Grinders set the standard for simplicity and automation. The unique rear roller mounting system (Figure 1) makes set-up on these machines more accurate than ever with simple machine decals guiding the operator on machine setup. This is the only design in the world that tells the operator where to place the rear roller based on reel make and diameter and is part of a pre-positioning system that provides needed clearances for both the spin and relief grind process.

In addition to easy placement, the “rear roller to reel shaft parallel design” of many cutting units makes gauging a “one & done” process for most reels. This is achieved with a visual LED and “bubble-style” graphic system (Figure 2) that allows even the most inexperienced operator the ability to remove taper when spin grinding. In the past, you could twist the bedknife and take rollers out of parallel to compensate for a cone-shaped reel, but with shorter heights of cut, more rigid reel frames, and harder metals, keeping reels true is more important than ever.

Foley United Figure 2

Foley United’s AccuTouch Control, standard on a 653 and as an option on the 633, takes grinding automation to a new level providing an animated graphic tutorial making setup quick and easy. With turn-over in shops, this is a priceless tool that will walk a new technician step-by-step through the grinding setup helping to achieve the highest quality spin grind possible. For more experienced operators, the tutorial is easily turned off for a quicker “set-up & spin grind” feature. With labor cost rising and the availability of technicians tightening, these types of innovations from Foley United are saving superintendents both time and money. There is merit in owning equipment that can improve productivity with automation, as you tell the machine what you’re working on and the machine does the rest.

In addition to automation and easy placement, a counter-balanced spin drive motor (Figure 3) pivots and floats to connect directly to the reel. This is now the easiest connection in the world and requires no tools.

Foley United Figure 3

Recently the industry has been trending toward grinders that do more than just spin grind and Foley United’s new generation of tabletop reel grinders address why. The patented auto-index relief system and automation of the in-feeds makes returning reels to spec a “no-labor” proposition and Foley United’s relief design makes this option easier than ever.

The “shop tools” you use to take care of the cutting heads isn’t complete without a partnering bedknife grinder. Foley United’s 672 AccuPro has been the industry workhorse for years and now things are even better with automation. The time needed to sharpen a bedknife with the 673 is second to none. This is the only unit in the world that utilizes electromagnets, pre-sets angles and pre-aligns the bedknife so all the operator has to do is infeed.

Foley United’s line-up of grinding equipment is a cut above the rest. The complete line of grinders offers choices to fit your style of maintenance and also your budget with out sacrificing the quality and craftsmanship you expect from Foley United. See you at the GIS or visit www.foleyunited.com to see how we can best fit your needs.