EcoBunker helps create ‘land art’ at Rumanza

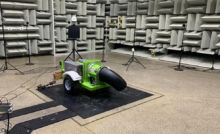

Rumanza EcoBunkers (Copyright Andrew Hagger)

The new Rumanza course in Multan, Pakistan, is using the EcoBunker engineered bunker edging system as a key part of its design.

The course, which is part of a 9,000-acre community being developed by DHA Multan, an agency of the Pakistani Ministry of Defence, was designed by six-time Major winner Sir Nick Faldo’s firm. Chief architect Andy Haggar explains: “The Rumanza site is extremely flat, and so we were obviously looking for ways to create movement and drama in the golf course. There are a lot of mango and citrus trees there, but outside those orchard areas, the site was just cereal crops and bare earth. That led us to select a links-style theme for the course, and that, in turn, led us to think about using EcoBunker. But the difference is that, on most links, the bunkers are relatively small, and that is definitely not the case at Rumanza. We do have some small bunkers, but most are fairly large, with big walls. There are also desert-style waste bunkers, where we have used the EcoBunker Advanced system to define the edge in key places. The course uses warm-season grass – paspalum – and so using natural turf to create the bunker walls would have been very difficult. The EcoBunker Advanced system was the answer: we’re always looking for new ways to be creative in our designs, and on a site like this, we had to go large, because anything small would just get lost.”

Haggar says that Sir Nick was very keen on the EcoBunker product. “Nick has known about EcoBunker for some time, but I’m not sure he had ever seen it in the flesh before, and he absolutely loved it. I could see his mind whirring and thinking about how we could use it – on this and other projects. It is the flowing shapes that you can create that he really likes – he calls it ‘land art’. We have a lot of that at Rumanza. I have to give credit to construction manager David Matthews – the shapes in the bunkers are fabulous.”

EcoBunker inventor and CEO Richard Allen says: “Rumanza is a fantastic showpiece that demonstrates not only natural stunning aesthetics and low maintenance qualities; it also highlights the importance of robust engineering. The high, steep walls underlain by deep in-situ sand present a technical challenge, and the EcoBunker Advanced system which we independently developed in 2016 was the perfect solution. My team and I have been actively involved, contributing to the early on-site design team workshops, followed by the training project from Llewellyn Matthews and ongoing technical support throughout. It is so exciting to see how the course has turned out.’’

Civil engineer Richard Allen invented the concept of synthetic bunker edges back in 2009 and founded EcoBunker Ltd. in 2014. Since then, the EcoBunker method has been used to build bunkers on around 400 courses in 34 countries.

Allen later modified his original construction method (which was patented in 2013) to create the EcoBunker Advanced system, introduced in 2016. EcoBunker Advanced uses a cement-modified backfill to create extra stiffness and stability, creating stronger revetted walls. EcoBunker welcomes inquiries concerning its system, which is patent-pending and invites anyone interested in it to make contact via ecobunker.co.uk.

Recent Posts

One of the Biggest Jobs in Golf

When Rory McIlroy finally slipped into the Green Jacket on Sunday, April 13, 2025, after…

Audubon International Marks Earth Day In Growth Mode

As the world celebrates Earth Day on April 22, Audubon International – the environmentally focused non-profit…

Help keep golf sustainable by bidding in GCSAA’s Rounds 4 Research online auction

In celebration of Earth Day, you can help fund the research that advances golf’s environmental…

Five Cabot Golf Courses Place in Golfweek’s Prestigious 2025 Top 100 International Courses List

Cabot, a developer and operator of luxury resort and residential golf destinations, is proud to…

Champion Hills Rebuilds with Heart: A Story of Resilience and Restoration

When Hurricane Helene swept through in late September 2024, Champion Hills Golf Club faced a…

Discover the New Graves Golf Club: A Game-Changing Facility in Edmond, OK

Graves Golf Club, the much-anticipated golf and training destination founded by celebrated instructors Tim and…