All-New Honda HRN Series Lawn Mower

Honda Power Equipment unveiled its all-new HRN Series of residential lawn mowers at the 35th-anniversary celebration of the Honda Power Equipment Manufacturing, Inc. (HPE) facility in Swepsonville, North Carolina. Replacing the popular Honda HRR Series, the innovative new HRN lawn mower offers a powerful new Honda GCV170 engine and added features that optimize grass cutting while streamlining operation and maintenance. The all-new Honda HRN Series of lawnmowers was designed from the ground up and tested at Honda Research and Development Americas, Inc. (HRA). The new models will be produced at the nearby HPE manufacturing facility. Both Honda operations are based in North Carolina.

Designed for People with a Passion for Lawn Care

The new Honda HRN Series of lawn mowers features four major areas of innovation: more power and torque, a rugged design, intuitive controls, and easier operation and serviceability than the HRR models they replace—all with the goal of making the task of grooming grass more productive and even more enjoyable for lawn care enthusiasts.

“Regardless of how popular or award-winning our outdoor power products are, Honda product development teams continuously pursue innovations that elevate each product for maximum performance and ease of operation for consumers,” said Will Walton, Vice President, Honda Power Equipment. “The all-new Honda HRN lawn mowers offer a powerful new engine, updated design and technologically advanced features that provide an easy, comfortable mowing experience and the smooth, groomed finish lawn enthusiasts aspire to. The new models are one illustration of how we at Honda Power Equipment are contributing to the Honda Vision for 2030—growth through the pursuit of quality and serving people worldwide with the joy of expanding the potential of lives.”

Power + Performance = Increased Mowing Efficiency

The heart of the Honda HRN Series is the all-new easy starting Honda GCV170 engine, delivering nine percent more power and 18 percent more torque than the Honda GCV160 engine in the outgoing Honda HRR Series of mowers. More power and torque relate directly to the ability of the machine to tackle tough mowing conditions while still producing the clean, even cut prized by people who care for their lawns. More torque means more force is being delivered to the blades, which results in easier and faster cutting—especially in heavy, thick grass where stalling can occur. The power and torque of the new Honda GCV170 engine provide more stable RPMs for greater consistency in cutting, mulching and bagging across a variety of lawn conditions. Increased displacement in the new GCV170 engine also contributes to more power and torque as compared to the GVC160 engine in the HRR Series.

The transmission has fewer parts for increased durability, and the new Honda GCV170 includes the exclusive Honda Auto Choke™ system. With a simplified structure and fewer parts, this user-friendly system is automatic, eliminating levers and cables. The engine starts easily, whether cold or hot and is ready for immediate mowing. Once the engine is running, the Auto Choke automatically returns to an optimal operating position. The Honda GCV170 engine also features the Honda exclusive CycloFlow™ design, which produces increased turbulence in the cylinder and more stable combustion, resulting in easy starting and greater resistance to lower-quality fuel. And even with more power and torque, the engine produces less vibration, which reduces fatigue and makes mowing more comfortable and enjoyable for the operator.

Intuitive Controls—Mind Over Matter

The Honda HRN Series of lawnmowers is designed with an array of intuitive controls for even smoother operating than the outgoing Honda HRR models.

Technologically innovative features begin with an improved design of the Adjustable Smart Drive® that allows for ease of speed variation with a press of a wide paddle control on the handlebar. In addition, a 3-in-1 Clip Director® lever located on the side of the engine cowling controls an entry shutter between the lawn mower deck and the grass bag, allowing the operator to easily:

- Mulch 100 percent of clippings

- Bag 100 percent of clippings

- Rear discharge

The operator can easily select either mulching or bagging options without the tools or attachments required on most conventional lawnmowers.

Other features of the HRN mowers include a simplified cut height control system consisting of a new dual-lever height adjustment (as opposed to four levers on the outgoing HRR models). With just two levers, the operator can make quick and convenient adjustments for seven different cutting heights, making it fast and easy to take a little off the top, make a deep cut or mow at standard maintenance heights. Finally, two-way releasing rear-wheel ratchets increase maneuverability by the reducing effort required to turn or pivot in tight areas. Overall, the system delivers maximum flexibility and ease of operation.

Sleek Design + Rugged Details = Dependability Designed from the Start

The Honda engineering team designed all-new Honda HRN Series lawnmower from the ground up. On the outside, the sweeping, modern engine fan cover, with its lustrous, Honda red paint scheme, suggests the same forward momentum as the lines in Honda automobiles and marine engines. The 21-inch curvilinear mower deck, designed for optimized airflow, is composed of heavy-duty steel to stand up to the most rugged conditions. The deck has been redesigned to produce an efficient path for grass clippings to pass into the bag or onto the ground when mulching. The efficient pathway improves bagging and mulching, preventing grass clippings from clogging.

Under the deck, the new HRN models feature precision-crafted blades with the exclusive Honda Twin Blade MicroCut System® for exact cutting and fine mulching at any height. Finer grass clippings make better mulch, and, when bagged, take less capacity in the grass bag. The result is fewer trips to empty the bag. For even greater durability, the front wheels have been reconfigured to a simple single axle, and nut and bolt connections are made of steel and embedded in resin.

Easy Operation + Quick Serviceability = More Free Time for the Operator

The Honda HRN Series is designed to make quick work of grooming grass, leaving more free time for the operator. The new HRN Series incorporates a fuel spout that is 60 percent wider than those featured on HRR models, along with an elevated oil spout that makes it easy to fill the gas or change the oil—reducing the potential for spillage. The design also features a smart engine layout with easy access to the spark plug, an optimized air cleaner that can be changed without tools. Even the handle on the 3-in-1 Clip Director® System has been redesigned, making it easy to slide the lever between the full bagging position and the full mulching position.

Born, Bred—and Assembled— in the USA*

The Honda HRN lawn mower is designed, tested and manufactured at Honda facilities in Swepsonville, North Carolina.* The existing 107-acre campus houses both Honda Power Equipment Manufacturing, Inc. (HPE) and Honda Power Product R&D operations. HPE produces a wide variety of general-purpose engines and numerous power equipment products including lawnmowers, snowblowers, trimmers, tillers, generators, and water pumps. The R&D team moved from its original base in Ohio to North Carolina in 1993 to be closer to power product manufacturing. As a result, Honda has deep collaboration between its power equipment development and production teams. This collaboration expedited the design and development process behind the all-new Honda HRN Series of lawnmowers.

One of the benefits of the collaboration involves improvements incorporated into the HRN Series models that have driven increased manufacturing productivity at the facility: every 20 seconds, one new Honda HRN lawnmower rolls off the Swepsonville production line, as compared to 24 seconds per the outgoing Honda HRR Series mower. The increase in production throughput allows Honda to control costs and more efficient supply customers.

Although Honda Power Equipment products are produced at 11 Honda manufacturing facilities worldwide, more than 75 percent of Honda power products sold in America are produced using domestic and globally sourced parts at the HPE manufacturing facility in Swepsonville, which opened in August 1984. More than 38 million Honda power equipment products have rolled off the lines during the past 35 years at Honda Swepsonville.

The Swepsonville operation has long served as a major producer of Honda power equipment products for worldwide distribution, with the capacity to produce more than two million general-purpose engines and more than 500,000 finished power equipment products annually. In 2018 alone, more than 131,000 North Carolina-made Honda power equipment products were exported to overseas markets. The total Honda investment in its Swepsonville operations is $350 million during the last 35 years, including the investment of $46.4 million announced today. The newest investment strengthens HPE’s production technologies and includes a 135,000 square-foot plant expansion that will house a new production line for Honda’s GCV general-purpose engine.

The Honda North Carolina centers of excellence are involved in the continuous development of world-class power equipment products. While providing product engineering, prototype development and testing, the associates work closely with suppliers to further the Company goals of technologically advanced products and local parts sourcing.

*Honda lawn mowers are made using domestic and globally sourced parts.

About Honda Power Equipment

Honda Power Equipment, a business unit of American Honda Motor Co., Inc., markets a complete range of outdoor power equipment, including generators, walk-behind and robotic lawn mowers, pumps, snow blowers, tillers, string trimmers, outboard marine engines and small, general-purpose engines for residential, commercial and rental applications.

Follow Honda Power Equipment news and video on:

YouTube: www.youtube.com/honda

Recent Posts

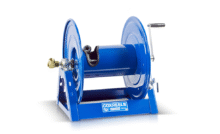

Coxreels® Exceeds Industry Recommended Salt Spray Testing Hours

Due to its numerous properties and, specifically, its corrosion resistance, powder coating is used for…

Advanced Turf Solutions and Arborjet | Ecologel Announce Strategic Partnership

Advanced Turf Solutions (ATS) is pleased to announce a new strategic partnership with Arborjet |…

BRANDT Expands Cup Format For Superintendents in Florida

The Florida Golf Course Superintendents Association proudly announces an extension and expansion of its successful…

The Rare Condor: What It Means for Golf and the Course Maintenance Behind It

Imagine this: you're on a par-5, having just hit your shot toward the green. You…

DENIOS Under Bench Cabinet Provides Safe Storage of Lithium-Ion Batteries

DENIOS introduces asecos under bench cabinets for the safe storage of undamaged lithium-ion batteries. They…

True Blue Golf Club, One of America’s Top 100 Resort Courses, Acquires Steve Dresser Golf Academy

True Blue Golf Club has acquired the Steve Dresser Golf Academy, a renowned instructional facility…